Silicone Product

-

Silicone Bag

View this collectionSilicone bags offer both personalization and design! They support customization, allowing for exclusive patterns, logos, and color adjustments to meet the unique expression needs of brands or customers. With strong design and development capabilities, these bags can be crafted into a variety of styles, from coin purses and cute cartoon bags to minimalist commuter bags and trendy crossbody bags. Whether it’s a rounded, adorable look or a sleek, minimalist style, each design can be accurately realized, helping clients capture the fashion market and providing partners with diverse, personalized options.

View this collectionSilicone bags offer both personalization and design! They support customization, allowing for exclusive patterns, logos, and color adjustments to meet the unique expression needs of brands or customers. With strong design and development capabilities, these bags can be crafted into a variety of styles, from coin purses and cute cartoon bags to minimalist commuter bags and trendy crossbody bags. Whether it’s a rounded, adorable look or a sleek, minimalist style, each design can be accurately realized, helping clients capture the fashion market and providing partners with diverse, personalized options. -

Silicone Stationery

View this collection

View this collectionSilicone Stationery

Silicone stationery offers significant advantages over traditional plastic stationery in terms of safety, practicality, and environmental friendliness. Its soft and flexible material is impact-resistant and less prone to breakage, ensuring long-term use without cracks, making it more durable than plastic. It is also safer for children to use. Customization of exclusive patterns, logos, and colors is supported, catering to brand promotion or personalized needs. With flexible design capabilities, it can be developed into various products such as cartoon pen grips and flexible rulers. Our strict production standards and quick order response enable us to provide customers with a diverse range of high-quality silicone stationery, creating greater value for partners. -

Silicone Toy

View this collection

View this collectionSilicone Toy

Silicone stress-relief toys are designed to help users release pressure and alleviate anxiety through actions like kneading and squeezing. Their appeal lies in the safety, durability, comfortable texture, and simple use of the silicone material. Our factory specializes in customizing silicone stress-relief toys. Whether you want whimsical and novel designs, fresh and soft color schemes, or personalized elements, we can bring your ideas to life. From creative concept to finished product delivery, our professional team provides end-to-end support to create exclusive stress-relief items for you, unleashing endless creativity. -

Silicone Keychain

View this collection

View this collectionSilicone Keychain

A keychain is not just a practical tool for managing keys—it's also a miniature fashion accessory that showcases personality. Our factory supports customization! Whether your company wants to print a brand logo for promotion or your team desires a unique commemorative design, we can bring your vision to life. From design conception and material selection to finalizing the shape, we provide end-to-end customization to create highly personalized keychains for you. -

Silicone Daily Necessities

View this collection

View this collectionSilicone Daily Necessities

Silicone household products are made of food-grade silicone material, which is safe, non-toxic, soft, and skin-friendly. They also offer water resistance, slip resistance, high-temperature tolerance, and easy cleaning. Widely used in kitchenware, home goods, and baby care products, they perfectly combine practicality with a healthy lifestyle, making them an ideal choice for high-quality daily living. Customization is supported! Whether your business wants to print a logo or create exclusive patterns and colors, we provide professional end-to-end service from design, material selection, to production. We help you create stylish and highly functional silicone products that meet diverse needs.

About us

Yiwu Yuefa Arts And Crafts Co., Ltd.

ESTABLISHED FOR 17 YEARS.

-

8,000m² 01

factory Area

-

100 + 02

Patent

-

150+03

Number of Employees

-

5,000+04

Cooperative Clients

Yuefa Arts And Crafts NEWS

Latest articles

-

Jan 23,2026

Jan 23,2026Silicone Toy Practical and Durable Everyday Helper

Silicone toys show up more and more these days, not just as random playthings but as things kids actually reach for during the day. The material feels...

-

Jan 16,2026

Jan 16,2026Kids Silicone Bag Practical and Durable Everyday Helper

Silicone bags show up a lot in kids' backpacks these days. The smaller ones made for children get pulled out constantly—school, car rides, park trips,...

-

Jan 09,2026

Jan 09,2026Silicone in Everyday Stationery – A Closer Look

These days you see silicone stationery showing up more and more in the kinds of things people use to hold pens, organize desks, or carry small supplie...

-

Oct 23,2025

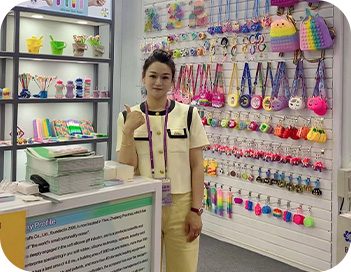

Oct 23,2025Trade City Store Officially Opens on October 10, 2025

Address: Yiwu Global Digital Trade Center, Unit 8, 2nd Street, 81446-81448

-

Sep 28,2025

Sep 28,2025Exhibition

Our advantages

Why work with us

-

01

Industry Deepening and innovation capacity

For 17 years, we have been dedicated to the field of soft silicone collectible toys, with over 200 Copyrights and patents. We have been recognized as a "National High-tech Enterprise" and continue to promote high-quality development in the industry through continuous innovation. -

02

Full industrial chain services

Integrating R&D, production and sales, we offer one-stop solutions from design to delivery. We provide free 3d product shape and appearance design, as well as one-stop OEM/ODM services. Respond quickly to customers' personalized demands and offer flexible customization. -

03

International quality certification

Produced strictly in accordance with ISO and GB/T standards, our products have passed the rigorous reviews of international giants such as Disney and Walmart, and our quality has been long-term trusted by globally renowned brands. -

04

Endorsement from top clients

We have established stable cooperation with international enterprises such as Disney, Walmart, Sanrio, Smiggle and DAISO, which validates the international standards of product design, craftsmanship and service. -

05

Professional team and refined management

With a team of over 200 experienced employees, we implement scientific and meticulous production management to ensure full-process quality control from raw materials to finished products, effectively enhancing production efficiency and on-time delivery rates, and providing customers with stable and reliable supply chain guarantees. -

06

Large-scale production capacity

Covering an area of 4.8 mu and with an 8,000-square-meter modern factory building, 11.5 mu (40,000 square meters) of new industrial land has been purchased for reserve. It has made forward-looking plans for future capacity expansion needs, equipped with over 80 sets of professional equipment, with an average daily production capacity of over 100,000 units, which can efficiently meet the demands of large orders.

What IP Licensing Means in the Silicone Industry

IP licensing is a structured commercial arrangement. The owner of an original creative asset (such as a character design, artwork style, motif, narrative theme, or symbolic element) grants permission to a manufacturer to incorporate that asset into specific product categories under clearly defined terms.

In consumer merchandise, this mechanism allows familiar visual or thematic content to appear in everyday usable objects rather than remaining limited to digital or printed formats.

Silicone stands out as a strong material choice for licensed goods due to the following properties:

- Superior flexibility across a wide temperature range

- Outstanding resistance to repeated mechanical stress and impact

- Safe, non-irritating contact with skin

- Ability to accept vibrant, stable pigmentation

- Capacity for both soft and firmer durometer grades within one production run

- Good resistance to moisture, oils, and everyday cleaning agents

Typical licensed silicone product categories include:

- Attachment points (key fobs, bag tags, zipper pulls)

- Device protection and grip accessories

- Beverage container sleeves, lids, and handles

- Small decorative and display pieces

- Compact collectible figures and charms

This combination creates a focused manufacturing niche that requires careful coordination between creative reference material, material science, tooling accuracy, and consistent volume output.

Primary Factors Driving Market Preference

Licensed silicone items gain traction because they blend emotional appeal with practical benefits.

Compared with rigid or display-only merchandise, silicone versions offer clear advantages:

- Natural fit into daily carry and use

- Comfortable, non-slip hand-feel

- High tolerance for drops and rough handling

- Lightweight construction that does not feel cheap

- Easy cleaning and long appearance retention

These traits encourage repeat purchases and word-of-mouth recommendation.

Factories adapt their workflow to meet these expectations through:

- Regular dialogue with rights holders and design studios

- Detailed conversion of flat artwork into moldable 3D forms

- Repeated review of scale accuracy, raised/ recessed detail depth, texture contrast, and color separation

- Long-term wear and handling tests on prototypes

Licensing also enables broader assortments under one theme:

- Office and study accessories

- Home and kitchen utilities

- Travel and lifestyle add-ons

- Small playful or novelty objects

Coordinated lines help distributors present stronger collections and improve inventory turnover.

Positioning in Cultural and Collector Segments

A significant portion of licensed silicone production targets enthusiast and collector channels.

Silicone performs well here because it delivers:

- Sharp reproduction of fine contour lines and undercuts

- Drop and impact resistance

- Reduce risk of fracture during shipping or long-term storage

- Stable appearance after months or years of display

For communities centered on character-driven stories, visual art, and franchise content, silicone provides practical benefits:

- Compact size supports affordable retail pricing

- Manageable batch quantities allow controlled scarcity releases

- Repeatable quality aligns with wholesale purchasing expectations

Manufacturing requirements in this segment include:

- Tight control over multi-stage color pouring or spraying

- Preservation of small raised details and engraved elements

- Consistent surface smoothness and absence of visible parting lines

- Uniform tactile response across an entire production lot

Production Equipment and Workflow Patterns

Contemporary silicone facilities rely on a mix of specialized machinery and skilled oversight.

Frequently used equipment categories:

- Precision dosing and mixing units for base and catalyst

- Compression molding presses with accurate temperature zoning

- Liquid silicone rubber (LSR) injection machines

- Automated part ejection and handling fixtures

- Dedicated deflashing, tumbling, and washing stations

These systems support:

- Tight dimensional tolerances across thousands of pieces

- Lower scrap rates in high-cavitation molds

- Predictable cycle times for planning large orders

Inspection relies on a combination of tools and trained judgment:

- Profile projectors and optical comparators

- Handheld and bench durometers

- Color matching cabinets and spectrophotometers

- Magnifying stations for surface and detail review

- Custom go/no-go gauges for critical dimensions

Technicians remain responsible for:

- Initial mold setup and ongoing adjustment

- Small-batch color trials and final shade approval

- Tuning of pressure, temperature, and cure profiles

- Release of first-article and periodic in-process samples

Standard Production Sequence

| Stage | Key Activities | Goals |

|---|---|---|

| Design & Engineering | Convert 2D reference to 3D CAD model Analyze wall thickness, flow, draft, undercuts Simulate shrinkage and detail retention | Ensure moldability and faithful reproduction |

| Mold Engineering & Build | Design single- or multi-cavity layout Select steel or aluminum based on volume Incorporate color-change or insert features Polish cavities to required finish level | Achieve repeatable shape, texture, and parting-line quality |

| Material Prep & Molding | Weigh and mix compound precisely Load molds with correct shot size Control press temperature and clamp force Monitor full cure cycle | Deliver consistent hardness, color, and strength |

| Finishing & Quality Verification | Remove flash and sprues Clean residual mold release Conduct visual check + sampling measurement Perform hardness, color, and tactile evaluation | Guarantee appearance, feel, and function meet specification |

| Packaging & Preparation | Apply protective wrapping if needed Insert into client-specified packaging Label lots for traceability Stage for shipment | Protect product integrity through distribution |

Benefits of Direct Factory Cooperation

Experienced purchasers increasingly favor direct relationships with production sites.

Core advantages include:

- Immediate access to current capacity and lead-time data

- Streamlined approval cycles for artwork revisions

- Reduced miscommunication on quantities and delivery windows

- Easier implementation of minor customizations (color shifts, added markings, packaging format)

- Clear documentation of tooling status and maintenance

Transparent management of these elements fosters longer-term collaboration:

- Ownership and depreciation of molds

- Prototype submission and sign-off procedure

- Production planning and priority rules

- Batch records and material certification

Silicone’s Role in Broader Markets

Silicone maintains steady growth across several industries:

- Sealing solutions for buildings and infrastructure

- Flexible components in transportation equipment

- Biocompatible parts for healthcare applications

- Heat-resistant and food-contact-safe consumer articles

Licensed consumer items leverage the same advancements in compound stability, molding precision, and finishing techniques that benefit the entire sector.

Focus Areas for Resource Responsibility

Factories continue to refine practices that lower resource consumption:

- Improving yield through better process control

- Extending mold service intervals with preventive care

- Reusing compatible trim material when technically feasible

- Selecting energy-efficient press and oven designs

- Right-sizing production runs to avoid excess setup waste

These efforts are often part of supplier scorecard discussions for repeat wholesale buyers.

What Buyers and End Users Should Think About

End-user expectations remain consistent:

- Confidence in material safety for regular handling

- Pleasant, non-sticky feel over time

- Ability to withstand normal drops and pressure without damage

- Reliable look and performance from one purchase to the next

Wholesale buyers add focus on:

- Color or texture drift between shipments

- Stable physical properties lot to lot

- Dependable documentation and on-time delivery

Closing Perspective

Licensed silicone products illustrate effective alignment between creative licensing, advanced material capabilities, and structured manufacturing.

Supporting pillars include:

- Accurate translation from concept to producible form

- Precision tooling that supports repeatability

- Balanced use of mechanization and skilled oversight

- Open, direct communication between factories and buyers

- Steady progress in efficiency and resource management

These elements allow silicone items to fulfill both thematic appeal and everyday practicality in a demanding consumer landscape.

As technical capabilities and market expectations continue to evolve, the licensed silicone category will stay closely linked to overall industry trends, offering clear pathways for collaboration among creators, producers, distributors, and retailers.

EN

EN English

English 日本語

日本語 Español

Español